DISCOVER OUR POWER FACTOR CORRECTION SOLUTION

Enjoy Improved Energy Efficiency Reduced Energy Cost

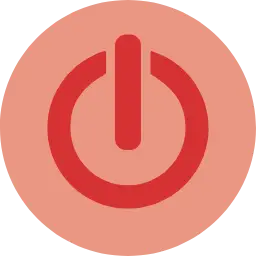

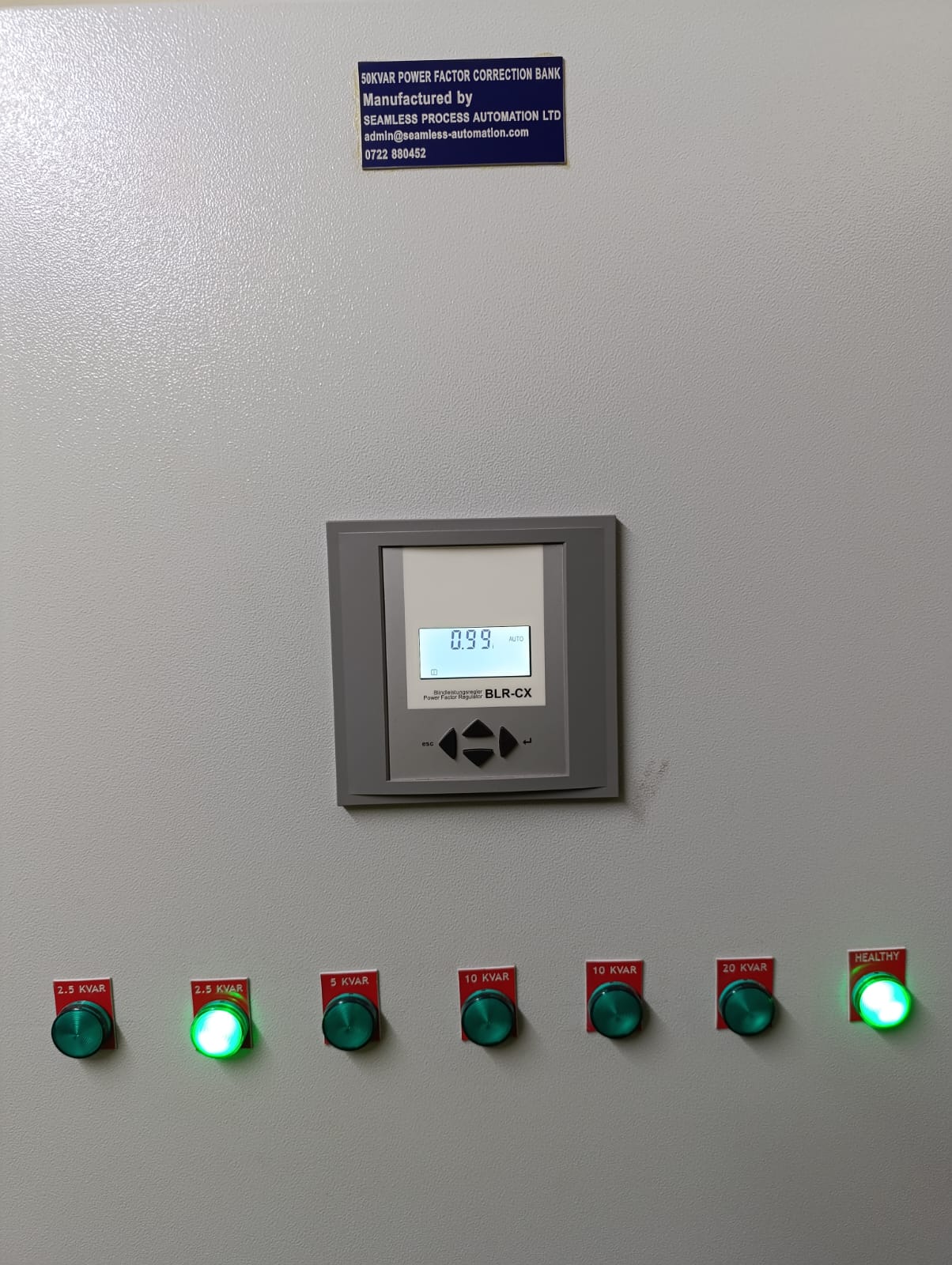

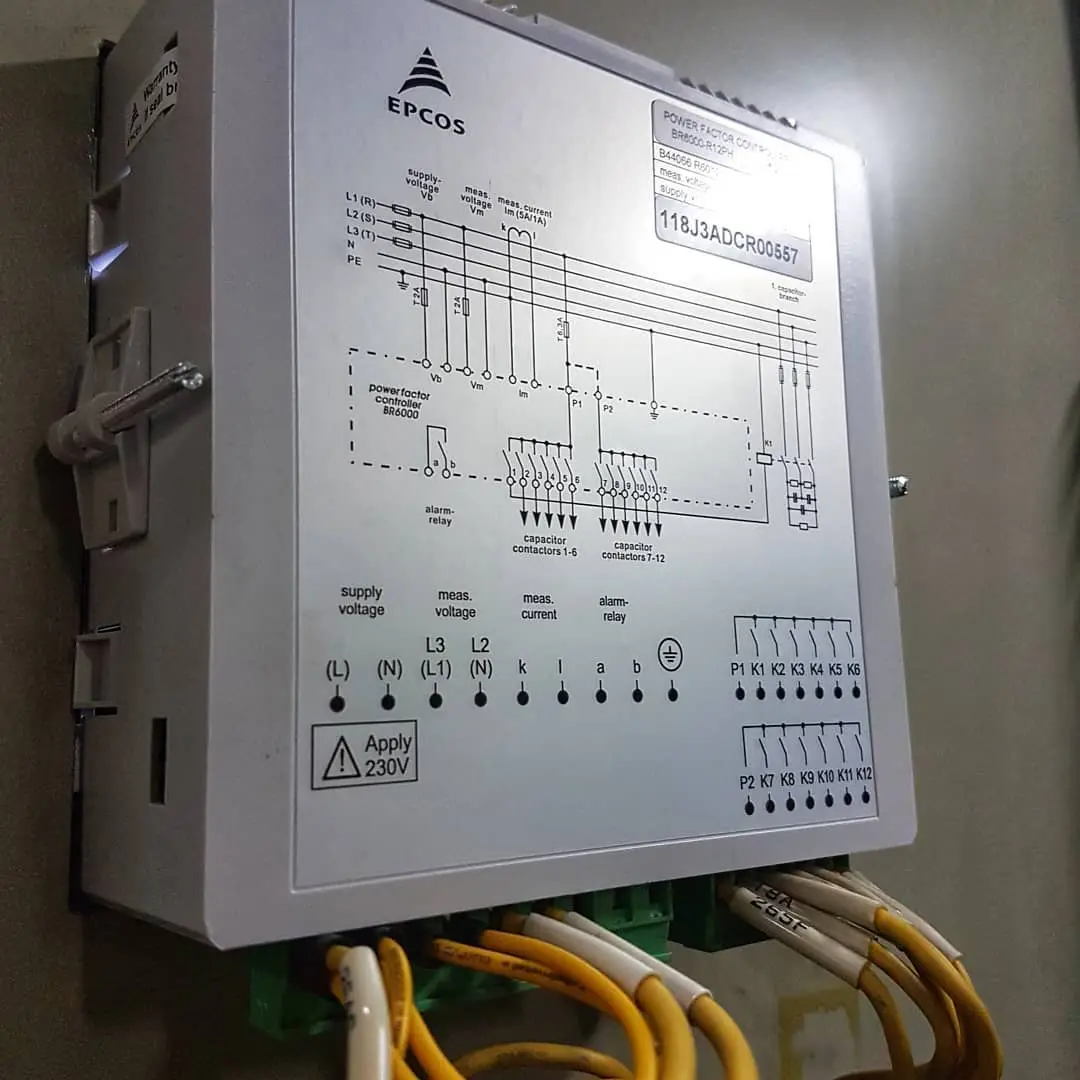

Seamless Process Automation Limited provide the most efficient power factor correction solution in Kenya. Our power factor correction panels, also known as capacitor banks, are built at our factory in Nairobi. They are fully tested before being delivered to site for installation and commissioning.

Power factor correction solution will involve either installing a brand new system or refurbishing / upgrading / repairing the existing unit. Each requirement is unique and thus every power factor correction solution will be tailored to meet customers’ specific need

Poor power quality cause serious adverse effects on the grid and result in unwanted trips, equipment damage, power failures, communication problems and system losses. Improving the quality, efficiency and performance of an electrical network with power factor correction systems extends the service life of the equipment, by reducing the risk of errors to obtain reliability, efficiency and sustainability in a network.

Power factor surcharge is applied by Kenya Power & Lighting Company (KPLC) when monthly average power factor value is below 0.9. Value of power factor refers to the ability of an electrical equipment to convert electrical current into useful work such as heat, light, mechanical motion…etc. To use electrical power efficiently systems should draw mostly real power, measured in kilowatts (kW), from the grid. If an equipment draws too much reactive power, measured in kilovolt-amperes-reactive (kVAR), it can’t perform work as efficiently and limits the capacity of power lines to deliver real power and quality voltage to customers.

Our Team

We have a strong power factor correction solution division that offers a comprehensive corrective and preventive maintenance services.

Maintenance Contract

Over time, power factor correction components deteriorate and declines the performance and lifespan of the unit. At Seamless Process Automation Limited, we offer planned maintenance contract to ensure power factor correction unit is working optimally.

Our services include the following

- Verify configuration for power factor controller

- Check for any deteriorated and or faulty capacitors, contactors, circuit breakers, cables etc

- Check axial fan and clean air filters to maintain optimal temperatures

Why do you pay for power factor surcharge?

When your power factor is below unity 1 (100%), your facility is drawing both reactive power and real power. However, the energy charges (cents per KWh) applied to your account only reflects the cost of providing you with real power you have consumed.

A power factor surcharge is applied to your account when your power factor is below 90%. It is used to recover the cost of supplying reactive power to you, which isn’t included in other charges. Ideally, real power should be equal to apparent power.

The total power a facility draws, also known apparent power, is the square root of the sum of the squares of real and reactive powers. The ratio of real power (kW) to total power (kVA) is called power factor (pf), and the equipment is performing best when that ratio is between 90% and 100% (0.9 to 1)

Power factor (pf) = Real power consumption (kW) / Apparent Power Consumption (kVA)

Impact of low power factor on electrical systems

- Voltage fluctuations

- Limits the capacity of power lines

Causes of poor power factor

Large inductive loads such as power transformers and electric motor driven loads such as fans, pumps and air compressors causes poor power factor. Additionally, loads that draw current in a non-linear fashion, such as computers, broadcasting equipment, compact fluorescent and LED lighting, electrical chargers, induction furnaces and many other devices may also contribute to low power factor in a customer’s system.

Good places to start your investigation are:

- Large fans and motors

- Equipment with a high number of transformers (such as lighting ballasts)

- Failed or improperly sized capacitors (if there is existing power factor correction unit)

- Harmonics in a system caused by non-linear electrical loads

How to correct poor power factor

Depending on the cause of your low power factor, there are different solutions that may be appropriate. Some examples are:

- Capacitors are commonly installed in electrical system where the cause of the poor power factor is a linear inductive load, such as an electric motor . Capacitors produce a leading power factor to counteract the lagging power factor of inductive loads.

- Harmonics filters may be needed in your system to improve power factor if the cause is a non-linear load.

- Sometimes operational changes in a facility are all that are needed to improve power factor. For example, you can operate a motor closer to the full-load rating.

Savings & Benefits of Power Factor Correction

The financial savings & benefits of power factor correction bank can by substantial and generally are achievable from the following areas:

- Removal of penalties on electricity bill in the form of reactive power charges

- Reduction in power consumption kw/h losses

- Reduction in capacity charges / authorized supply capacity

- Reduction in carbon emissions

- Reduction in circuit currents

- Reduction in maximum demand and demand based charges

- Improvement in power quality

The payback period of power factor correction bank is typically between 1 – 3 years’ dependent mainly on three things:

- The structure and type of the electricity bill

- The degree of inefficiency to be corrected

- Type of power factor correction required

Features of a Power Factor Correction Capacitor

- Three-phase delta-connected

- Self-healing technology

- Dry-type

- High inrush current to cope with circuilation of harmonic current

- Fastening assured by clamp tight terminals

- Large voltage variation and can thus be used in systems where non-linear loads are present

Our Partners

WHY CHOOSE OUR CAPACTOR BANK

- Metal enclosures designed for easy installation and maintenance

- Top quality capacitors with protection against internal overpressure

- High quality protection devices used (breakers, contactors, aux. controls etc.)

- Fully programmed power factor controller, can be configured for fixed or variable compensation

- Proper Ventilation system

- Halogen-free cables

Design

Selecting the size of power factor correction bank is preceded by comprehensive preliminary assessment of equipment ratings and electricity bills.

Our careful design and top-quality components guarantee excellent performance.

Dedication

Our engineers and technicians always carry vast array of spare parts to unsure complete power factor correction solution is offered within shortest time possible

Sectors

Our sectors of excellence include manufacturing, food & beverage, aggregates & bulk handling, pharmaceuticals, civil infrastructure, commercial buildings, healthcare among others

Call or Write to us

We assure optimised technical and commercial proposal