DISCOVER OUR ELECTRICAL PANELS

Seamless Process Automation Limited offers extensive bespoke selection of electrical panels designed to meet various applications across construction, industrial, commercial, hospitals, agricultural among other sectors. We have a proven track record of excellence in implementing simple and complex projects with proficiency. Each project receives the same top-quality workmanship and dedication.

Our range of electrical panels are designed in the following structures

- Free Standing

- Floor-mounted

- Wall-mounted

- Turret

- Feeder Pillar

Our designs allows for intelligent layout and safe access, including rear and front cubicle access, suffient cableways and multiple alluminium glanding plate.

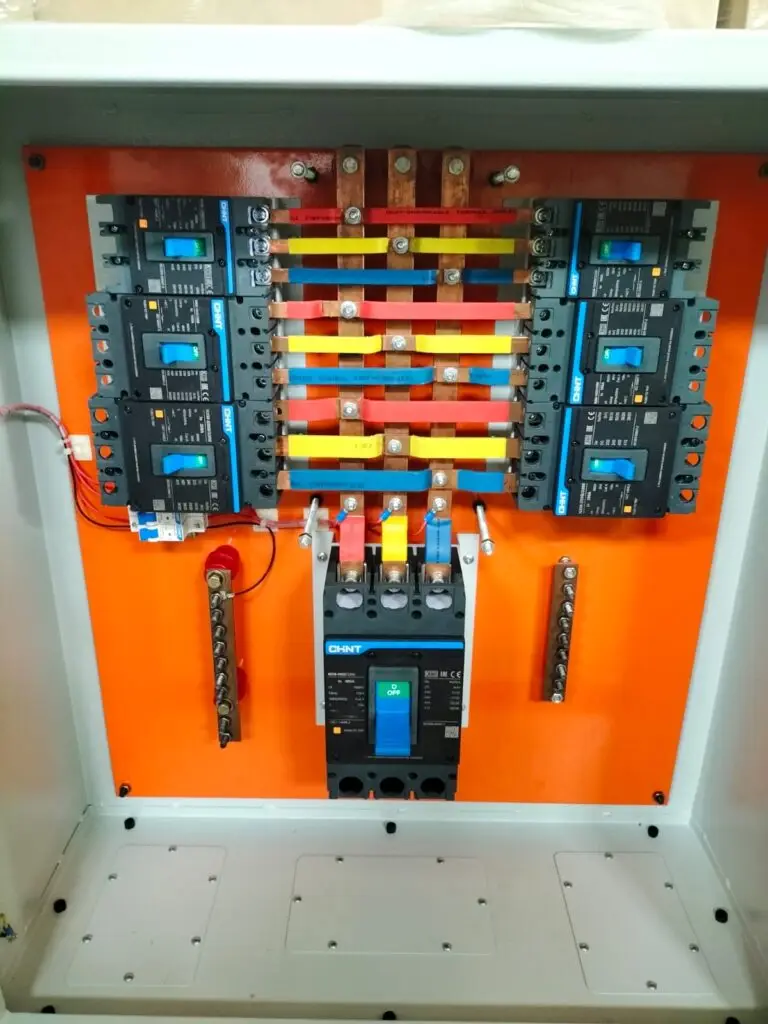

We customize our electrical panels to fit majority of switchgears available in Kenya, they include ABB, Schneider Electric, Siemens, Chint Electric.

Free Standing Electrical Panel

Free Standing electrical panels are often used as main power reception from Kenya Power & lighting Company (KPLC) transformer. They are ideal for applications whose load is 300KVA and above. The panel is made of an enclosure which is properly designed for thermal management and accessories appropriate for landing incoming power cables and delivering distributed power.

Free standing panels can be manufactured in compact or modular design. Modular design means the panel can be extended in future by adding new cubicles complete with switchgear to the existing panel.

Features

- Rating 250A to 6000A

- Material – Powder Coated Mild Steel

- Compact or modular design

- Ingress Protection IP20, IP31, IP42, IP54

- Indoor Installing

- Cable Entry / Exit – Top / Bottom

- Separation – Form 1,2,3,4

- Panel Access – Front / Rear

Floor Mounted Electrical Panel

Floor Mounted electrical panel is a cost effective solution for mid-sized panel design from 100A to 630A. The panel can be used for power distribution, motor starters, marshalling cabinet

Features

- Rating 63A – 630A

- Material – Mild, Galvanized or Stainless Steel

- Ingress Protection IP54, IP66

- Indoor / Outdoor Installation

- Cable Entry / Exit – Bottom

- Separation – Form 1

- Panel Access – Front

Wall Mounted Electrical Panel

Wall mounted encosure provides organised, secure, simple and cost effective housing for electrical equipment, ensuring accessibility, protection and space efficiency in buildings and industrial facilities

Features

- Rating 63A – 630A

- Spot weld construction

- Mounting holes at the back of enclosure

- Material – Mild, Galvanized or Stainless Steel (1.5mm – 2mm thick)

- Ingress Protection IP54, IP66

- Indoor / Outdoor Installation

- Cable Entry / Exit – Bottom / Top

- Separation – Form 1

- Panel Access – Front (120 degrees opening front door)

Feeder Pillar

Feeder pillars provide effective outdoor low voltage power distribution, motor starters, lighting. They are applicable in industrial and non-industrial applications

Features

- Rating 63A – 630A

- Spot weld construction

- Material – Mild, Galvanized or Stainless Steel (1.5mm – 2mm thick)

- Ingress Protection IP54, IP66

- Indoor / Outdoor Installation

- Cable Entry / Exit – Bottom

- Separation – Form 1

- Optional Ventilation Louvres

- Panel Access – Front (120 degrees opening front door

- Document pocket

Turret

Turret is an outdoor panel used to distribute power from a transformer. It is ideal for an estate with multiple houses sharing the same transformer. Several turrets can be daisy-chained allowing for effective power distribution. Turrets are supplied fully assembled with busbars and protection devices such as MCBs and / or fuses complete holders.

Features

- Rating 63A – 1600A

- Spot weld construction

- Material – Mild, Galvanized or Stainless Steel (1.5mm – 2mm thick)

- Ingress Protection IP55

- Outdoor Installation

- Cable Entry / Exit – Bottom

- Separation – Form 1

- Panel Access – Front (120 degrees opening front door)

- 2 doors

ELECTRICAL PANEL BUILDING PROCESS

Enquiry / Consulting

Our team of experienced professional sales engineers engage customers to collect technical details. They perform full site inspection and together with the customer a functional design specification document is prepared.

Quotation

A detailed technical and commercial offer is prepared comprising of electrical and mechanical specifications. The quotation is share with the customer for approval.

Engineering & Design

A project manager is assigned to unsure seamless communication during the entire period of project execution.

A preliminary design is prepared including layout and concept from project implementation to final site installation. The following documents are prepared

- Electrical Panel Design & Specifications

- Concept design & Layout

- CAD Drawings

Turn-around time for this process is within 48-72 hours. CAD drawings are shared with the customer for approval.

Electrical Panel Building

Once drawings are approved by the customer, sheet metal fabrication and electrical assembly begins. Production usually takes 1 to 4 weeks based on the complexity of the panel. Upon completion, the following Factory Acceptance Tests (FAT) are carried out

- Insulation Test

- Primary Current Injection Test

- Secondary Current Injection Test

- Visual Inspection

- Metering Current Transformer Polarity Test

Installation and Commissioning

Before installation begins, the electrical panel is tested to ensure it wasn’t damaged during transportation. These tests include insulation test, polarity test, earth electrode resistance test.

After installing the electrical panel, the following tests are performed; verification of voltage, phase sequence, functional testing and earth fault loop impedance.

Post-commissioning

- We provide comprehensive documentation upon project completion. They include

- Layout and Schematic drawings

- Bill of quantities

- Test report

- Training Manual and Catalogs

- Recommended Preventive Maintenance

We provide our customers with unmatched technical support. For intensive operation where system uptime is imperative, we sign up maintenance contract to ensure preventive maintenance is done consistently thereby minimizing costly downtime and breakdown costs.

Our comprehensive range of preventive maintenance include

- Variable Frequency Inverter maintenance

- Infrared Imaging

- Testing and Tagging

- Earthing Resistance testing

- Emergency lights testing

ELECTRICAL PANEL MAINTENANCE CONTRACT

Seamless Process Automation Limited offers full-range support, corrective and preventive maintenance services to ensure your electrical automation systems operate at peak efficiency and minimal down-time.

We provide on-site support, remote support and spare part packages to maintain systems up-time.

Gallery - Electrical Panel

Call or Write to us

We assure optimised technical and commercial proposal