Fiber Optic Splicing

Seamless Process Automation Limited is a renowned contractor in Kenya offering fiber optic splicing services with precision and reliability.

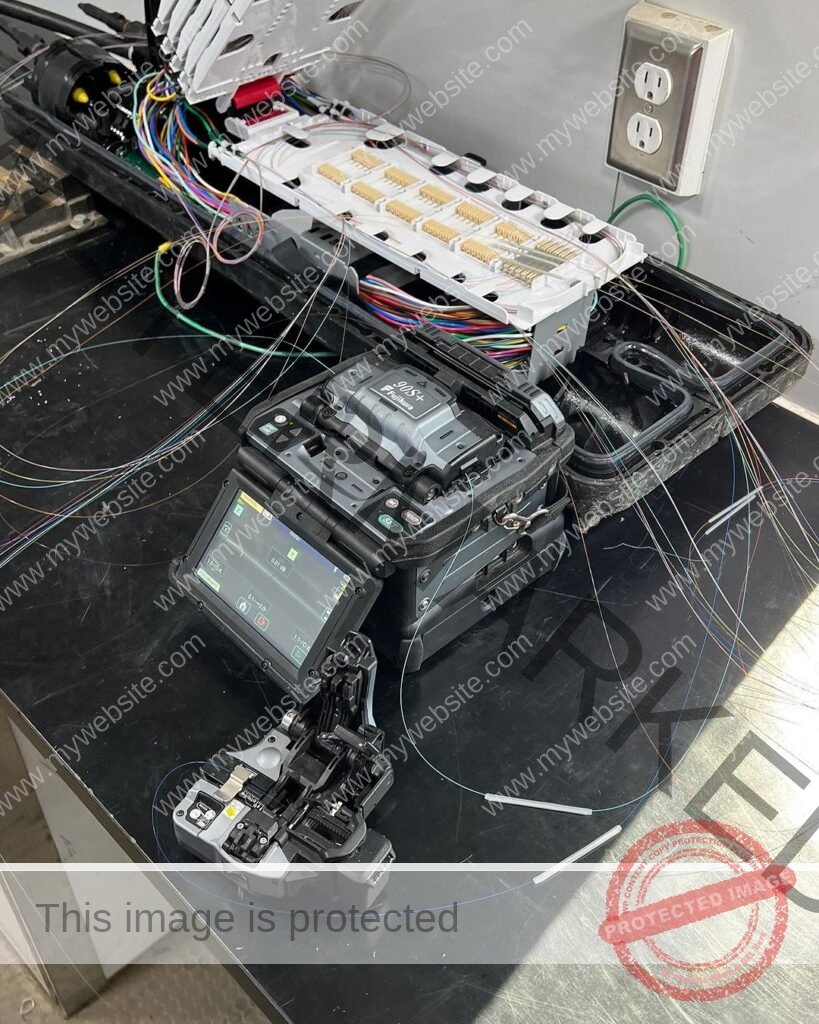

We are equipped with the latest fusion slicing and testing equipment that guarantees high performance and fast speeds.

Our Fiber Optic Team

Our team consists of certified fiber optic engineers and technicians with vast experience in handling diverse projects within the industry. We provide highest level of workmanship, professionalism, expertise and knowledge in our fiber optic splicing works. Seamless Process Automation Limited has a proven record of working to highest specification standards with majority of prominent business organizations in Kenya ranging from commercial offices, industrial plants, warehouses to data centers.

Our in-house team enables us provide quick response to urgent and emergencies. We also come equipped with significant number of spares / accessories such as patch cords, pigtails, sleeves, network switches, patch panels among others

Fusion Splicing

We offer field engineers and technicians for on-site fusing fiber optic splicing services

At Seamless Process Automation Limited, we are trained and well equipped to carry out wide range of fusion fiber optic splicing services. We always perform pre-splicing analysis to determine all requirements before commencing the job.

We support fusion splicing requirement for both single-mode and multi-mode fiber cables.

Our fusion splicing services include

- Aerial Fiber Optic Splicing

- Premise (office) multi-mode splicing

- Telecom splicing

- Emergency restoration

- Data centre installation

Splicing Process

It is a delicate process that if not well done can cause outage or poor connectivity. Below are steps followed in a typical fusion splice

- Using fiber stripper, remove coating in a fiber core

- Clean the fiber with alcohol-laced wipes to remove contaminants

- Using a cleaver, make a straight cut and allow sufficient allowance for fusing

- Place fiber joint conveniently in the splicing machine, the machine will make a permanent weld

- Protect the welded joint with heat-shrink sleeve

- Use Optical Time Domain Reflectometer (OTDR) to test the new connection and ensure there is no loss or faults